Our CSR policy

A naturally responsible business model

As a bespoke solutions company, sustainability is at the heart of our business model. We are committed to delivering a quality service while minimising our environmental impact. We always strive to create the conditions for a trusting and respectful environment with our employees and all of our stakeholders.

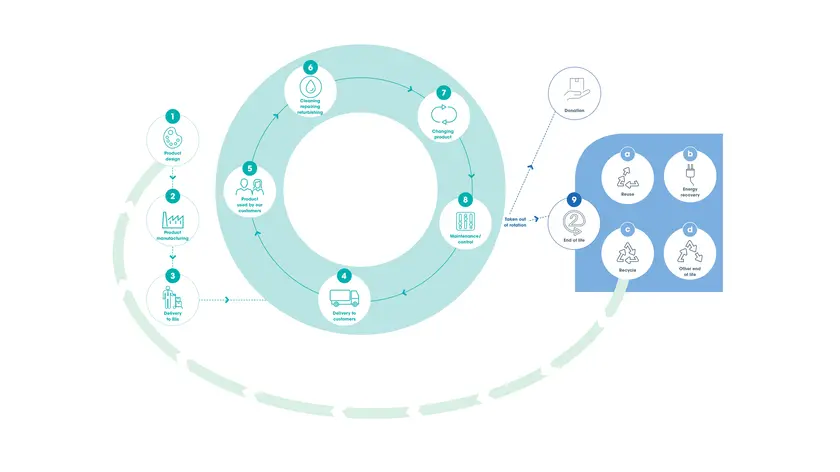

Our business model and our success has been based on the circular economy aspect.

At Elis, circular economy is at the core of our business model and the foundation of our CSR Strategy.

We strongly believe that circularity is one of the solutions to face the current environmental challenges!

What is sustainable development at Elis?

Our business model is responsible by nature.

Our bespoke solutions model allows our customers to benefit from our services without having to buy the products they need. Because we maintain the products that we offer for rental, our offering naturally tends towards product lines that are designed to last.

This circular economy approach maximises the use of products, encourages their recycling and so reconciles economic growth with environmental impact.

But we are not stopping there. We use eco-designed products to promote alternatives to disposable products, and we work with our suppliers to minimise waste at the source. We optimise every kilometre travelled when it comes to logistics – an essential part of our strategy to be closer to our customers. For example, we use an eco-driving box placed in the service agent’s vehicle that calculates fuel consumption and advises the driver in real time. We are also reducing consumption of water, energy and laundry products at our industrial sites.

Our objectives are to:

- reduce our consumption of water, energy and laundry products by 25%

- work towards zero waste

In 2019, Elis has defined new ambitious objectives for 2025, regarding a more efficient use of resources (water, energy, chemicals), textile recycling, product sustainability or employees well-being.

Elis' circular economy

Our commitments

-

Circularity and exemplarity to reduce our impact on the planet

-

Empower our employees and support their development

-

Make a positive impact for society

Our objectives for 2025

-

80%

of textiles reused or recycled at the end of the Group's life

-

-20%

reduction in CO2 emissions intensity in Europe (compared to 2010)

-

-50%

less water consumption in Europe (compared to 2010)

-

-35%

of energy consumption in Europe (compared to 2010)

-

-50%

in lost time accidents

-

95%

of our preferred suppliers covered by a CSR assessment

Our climate strategy

Our CO2 emission reduction targets have been approved by the Science Based Targets initiative (SBTi) – an international reference.

These objectives are fully in line with the objectives of the 2015 Paris Climate Agreements to contribute to restrict global warming to less than 1.5°C compared to pre-industrial levels on Scope 1 and 2, and well below 2°C on Scope 3.

- SCOPE 1 and 2 : - 47,5 % *

Reduce absolute GHG emissions from direct emissions and indirect emission of the Group (eg: electricity, gas, diesel…)

- SCOPE 3 : - 28 % *

Reduce absolute GHG emissions from purchased goods and services, fuel and energy related activities, upstream transportation and distribution, employee commuting, and end-of-life treatment of sold products

*by 2030 from a 2019 base year

Sustainable product lines

Sustainability is embedded in our business model and is core to our strategic vision. We develop innovative, durable, repairable and recyclable items. By 2025 we aim to offer at least one workwear collection made of 100% sustainable materials for each of our product groups.

-

Fair trade industry

Our Bio’s Fair bathroom linen, made from 100% organic fair trade cotton with a Max Havelaar label, guarantees comfort for your customers.

-

Eco-designed mats

Our floor mats are made from Phoenix fibres that are 100% produced from recycled water bottles.

-

Cradle to Cradle certified®

Our FUSION washroom collection is Cradle to Cradle Certified®. Assessed for its environmental and social performance across five critical sustainability categories, this certification is recognised globally as a measure of safer, more sustainable products made for the circular economy. It is a preferred product standard for responsible purchasing decisions for a growing number of brands and organisations across the globe.

-

Ecolabel for washrooms

Consumables in the Natur’Elis line carry the EU Ecolabel, certifying reduced environmental impact throughout their life cycle.

Real results

-

-40 %

of water consumption since 2010, per kg of linen treated (Europe)

-

34%

of new managers are women

-

16%

of new managers are promoted internally

-

72%

of textiles reused or recycled by 2021

Non-financial ratings and prizes

For the 6th year Elis received the Gold Medal in the EcoVadis questionnaire with a score of 75 points.

This medal positions the Group in the top 5% of the companies assessed by EcoVadis.

This crucial questionnaire for the customer-supplier relationship assesses companies on 21 aspects grouped into four themes (Environment, Labor & Human Rights, Ethics and Sustainable Procurement).

The Group achieved an A- the second time it participated in the climate questionnaire conducted by the Carbon Disclosure Project (CDP), compared with its B in 2021. The CDP is a non-profit organization that carries out independent assessments (with ratings ranging from D- to A Leadership) based on information provided by companies on their strategy, management, performance or even their role in engaging with their stakeholders about climate issues. The Elis Group is thus positioned higher than the average score for the sector in Europe (C) for this first reporting year, in the top 8% of companies engaging with their supply chain on climate.

In 2022, Sustainalytics significantly upgraded Elis’s ESG rating by nearly 10 points to 14.8 (“low risk”).

Elis maintained its excellent score from the Gaïa rating agency (72/100), putting it in the Gold category.

Innovation

Every year since 2008, we have set targets to reduce our water, energy and detergent consumption by 3-5%, following a proactive investment policy.

Our processing sites are equipped with high-performance technologies. Heavy-duty washing tunnels have been deployed across all sites. They process batches continuously, allowing optimal energy consumption by increasing how much linen is washed. Air to air and water to water heat exchangers are installed to save energy, while recycling systems are automated to recover water from one stage for use in another, where possible.

Clean water from the rinsing stage is reinjected into the pre-wash compartments, allowing water, laundry detergent and energy to be saved.

In Sweden, five laundries use biogas, saving 4,000 tonnes of CO2 a year.

On the logistics side, delivery routes are optimised with the help of dedicated software to reduce the kilometres travelled.

An increase in the number of clean vehicles

Our objective for 2025 is to significantly increase the number of eco-friendly vehicles while seeking to reduce fuel consumption of thermal vehicles, improve our fleet management tools, promote eco-driving and maximize the filling rate of our trucks

Since July 2020, 10 small trucks joined the Elis car fleet in France; they stengthen the Group's clean fleet to make a transition to more sustainable, cleaner and more responsible mobility.

Whistleblowing Policy

The Group’s ethical and responsible conduct is key to its success and longevity, and Elis is committed to building trust with its employees, customers, suppliers, partners and more broadly, all of its stakeholders. The principles of respect, integrity, responsibility and exemplarity constitute the foundation of the Group’s commitments, as reflected in its Code of Ethics.

The Group therefore provides a whistleblowing line, accessible to everyone, anywhere in the world, to report any situation contrary to Elis’ Code of Ethics, including any situation that violates applicable laws and regulations, as well as any risk of serious harm to human rights and fundamental freedoms, human health and safety, and the environment.

This alert system allows for anonymity and guarantees the confidentiality of information at all stages of the investigation.

The Group undertakes to protect whistleblowers from any negative consequence or retaliation, provided that reports are submitted in good faith, even if the facts reported are ultimately not confirmed. The alert line is accessible 24 hours a day, 7 days a week, to address a written or voice message in one of the Group’s 18 local languages.

Download the Whistleblowing Policy

Discover also

Want information on all of our services?

Need information? Contact us!

*Required fields

Contact details

Your legal name is the name that appears on your official documents.