Innovation at Elis

Innovation at Elis

Elis has always been innovating and diversifying it's hygiene and well-being services ever since it was created in 1883. We are now living in an era of big change, both in terms of digital technologies and uses, and this innovative spirit is still alive, meeting new customer demands, creating new services or optimising existing ones.

Design innovation: from need to solution

Everything begins with a customer (internal or external) telling us what their needs are. We then seek to create the optimal solution for them. Supervised by Innovation project managers and following approval from a dedicated committee, independent teams dispatched to our various departments begin working on an R&D phase, before conducting feasibility studies and several POCs to test the solution they have come up with. We use design thinking with iterative development and short decision-making circuits. Once the customer signs off the solution, it is then rolled out with assistance from the usual central support services.

This work is helping to create ground-breaking solutions, such as smart washroom appliances, digital sizing tools and even sales support tools that use augmented reality technology.

Increasing innovation partnerships

Elis welcomes technological innovations developed outside the company so that it can adopt the most promising advances early on and adapt them to it's business as quickly as possible.

This approach has led to a dozen or so partnerships with start-ups and innovative SMEs with the potential to complement our offering.

Four flagship Elis innovations

-

Eco-designed mats

-

Smart washrooms

-

Next generation sizing

-

Augmented reality

Limit your workwear environmental footprint

By washing at Elis you will save:

Find out more about the results

The figures come from the comparative LCA « Providing the wearer with a clean, dry working outfit 5 days per week, every week for 4 years service ». The LCA went through a critical review process in line with ISO 14071 requirements. Peer board members were LCA and washing industry experts.

These results are indicative based on 1 jacket and 2 pairs of trousers per week per wearer.

Sensitivity analysis has shown that the results do not significantly change if the number of changes per week is altered.

Main assumptions:

Methodology: ISO 14040, 14044, Environmental Footprint 3.1 method.

Database: Ecoinvent 3.9.1, ADEME and Elis specific data.

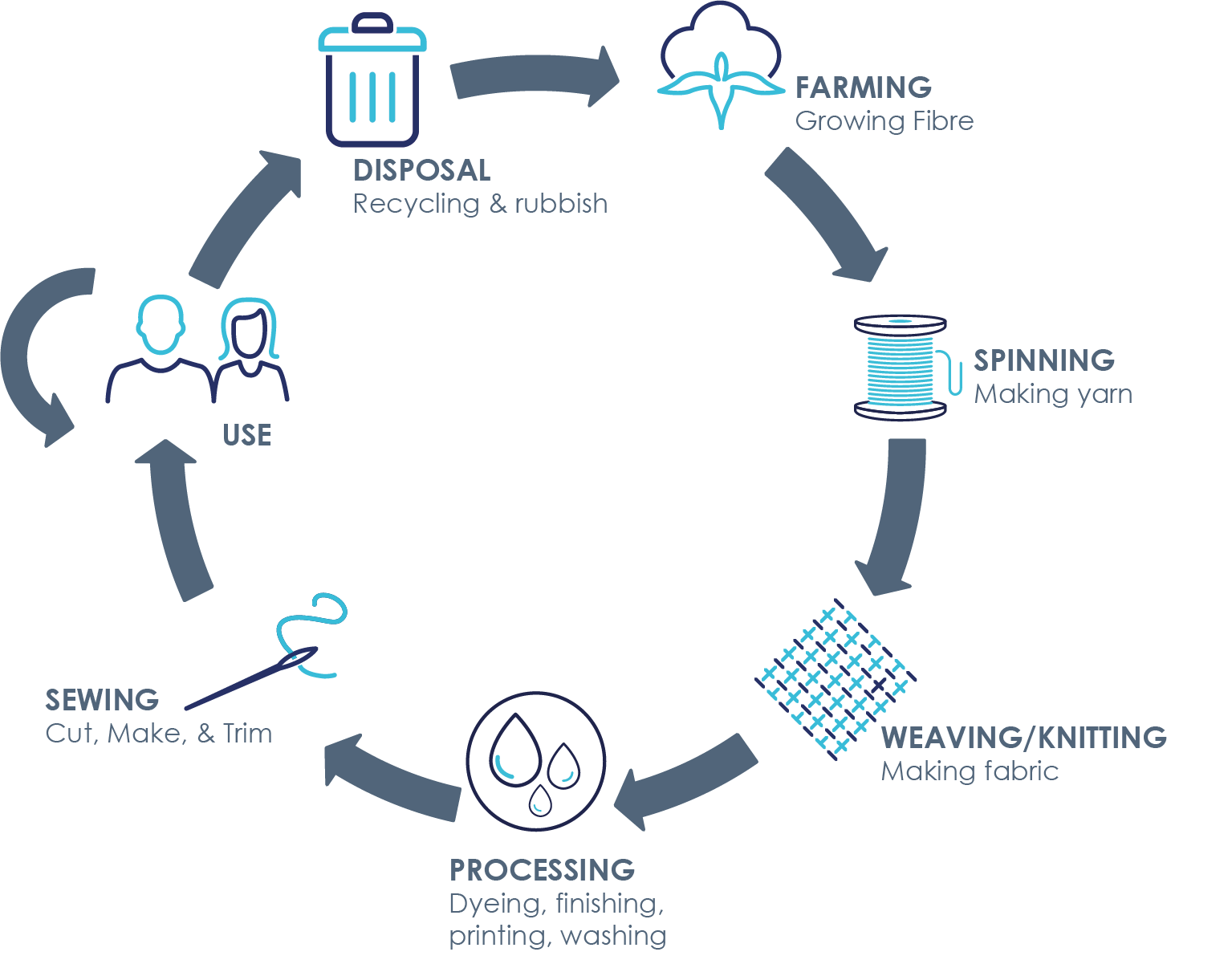

Steps analyzed in the LCA

environmental impact reduction

The results include the full life cycle from raw material to end of life, including the washing process and come from an ISO 14040 and 14044 LCA.

Elis, a leader in circular services, allows businesses to achieve optimal hygiene and protection for their employees and customers.

Elis offers its clients products that are maintained, repaired, reused, and reemployed to optimize their usage and lifespan. Elis’ conviction is that the circular economy model, which notably aims at reducing consumption of natural resources by optimizing the lifespan of products, is a sustainable solution to address today’s environmental challenges. The services offered by Elis represent a sustainable alternative to the simple purchase or use of products or to single use disposable products. 84% of the Group turnover (2023) are based on the product as service business model.

Elis has carried out a comparative Life Cycle Analysis (LCA) covering the full life cycle of workwear products.

The LCA compares 3 cleaning scenarios of a full workwear outfit (jacket and trousers); the circular model based on garment rental with scenarios where garments are purchased and cleaned at home or purchased and cleaned

by a laundry service.

The results come from the comparative LCA “Providing a wearer with a clean, dry working outfit 5 days per week , every week for 4 years’ service”. The LCA went through a critical review process in line with ISO 14071 requirements. Peer board members were LCA and washing industry experts.

Methodology : ISO 14040, 14044, Environmental Footprint 3.1 method Database: Ecoinvent 3.9.1, ADEME and Elis specific data.

These results are indicative based on 1 jacket and 2 pairs of trousers per week per wearer. Sensitivity analysis has shown that the results do not significantly change if the number of changes per week is altered.

Latest news

Discover also

Need information? Contact us!

*Required fields

Contact details

Your legal name is the name that appears on your official documents.