Phoenix washroom dispenser: 30% reduction in environmental footprint

An innovative design

The Phoenix range has been designed to have a reduced impact on the environment. These hygiene dispensers are all made from recycled ABS* plastic, with the feminine hygiene container containing up to 98% recycled ABS.

These dispensers are manufactured in Europe. For more than 75 years, Elis has been offering protection, hygiene and well-being solutions with a lower environmental impact through its circular services.

*Acrylonitrile butadiene styrene

What is an LCA?

A Life Cycle Assessment (LCA) assesses the environmental impact of a product throughout its life cycle – from the extraction of raw materials to manufacturing, transport and beyond. This method makes it possible not only to evaluate the environmental footprint of each stage in a product’s life cycle – and therefore to identify which stages have the greatest impact, as well as avenues to reduce this – but also to compare different solutions to each other.

It measures the footprint as regards various environmental challenges: climate change (carbon footprint), consumption of resources (water consumption, use of fossil fuels, consumption of mineral and metallic resources), pollution (emission of fine particles, acidification etc.).

A simplified LCA was carried out to assess how offering a hygiene dispenser made from recycled materials instead of virgin plastic reduced environmental impact. It compared the Phoenix P2F dispenser to its virgin plastic equivalent.

A rigorous methodology

The LCA was carried out from cradle to gate – in other words, from the raw materials, through production and upstream transportation, up until the dispensers leave the supplier’s logistics site.

The methodology and database used are rigorous and widely recognised: the European Product Environmental Footprint (PEF) methodology on the one hand and the Ecoinvent database, known for its reliability and extensive dataset, on the other.

To model the dispensers, specific data on the dispensers (weight, composition, energy consumption) was collected.

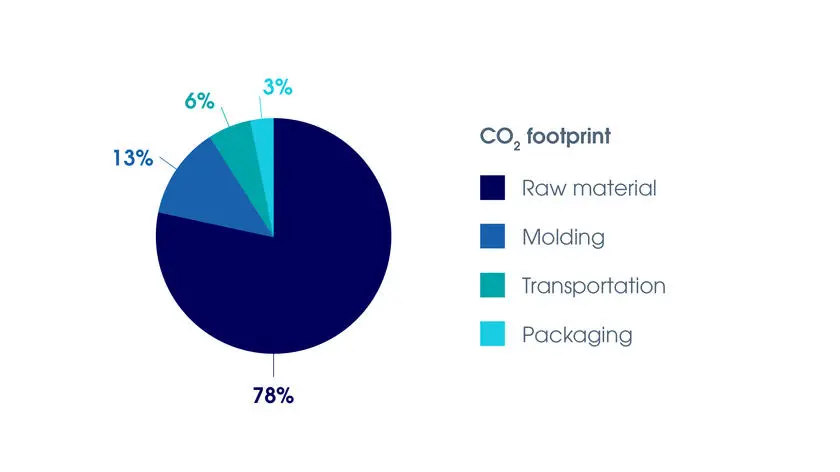

The analysis showed that 75% of the dispenser’s carbon footprint comes from its raw materials.

Key figures* *Results for the P2F paper towel dispenser.

-

30%

reduction as regards the major environmental challenges

-

90%

of virgin plastic avoided

The LCA on video

For a deeper dive, discover this testimonial from Lucie, who carried out the study.

A minimal environmental impact

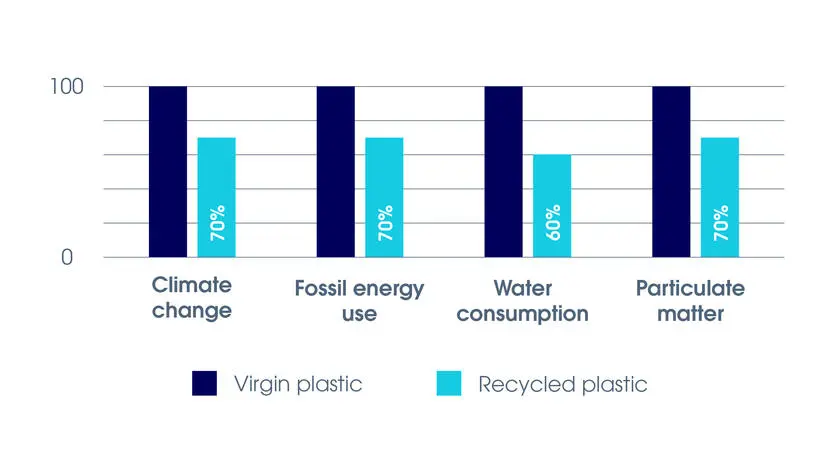

This analysis, which compared a hygiene dispenser made from virgin plastic with its recycled-plastic equivalent, identified two key takeaways:

-

Reduced use of resources: By using recycled materials, the Phoenix paper towel dispenser reduces the amount of virgin plastic used by 92%.

-

Reduced emissions: 30% reduction as regards the major environmental challenges. This includes climate change, fossil fuel consumption, water consumption and emissions of fine particles.

Products of Phoenix range

Q&A

-

What does the scope of the LCA include?

-

Why are two products from the Phoenix and Aqualine ranges being compared?

-

Who carried out this LCA?

-

What is ABS plastic?

-

Where can I find the full LCA results?

Contact Us

Need information? Contact us!

*Required fields

Contact details

Your legal name is the name that appears on your official documents.